◇ Currently, most of the raw materials such as nickel and cobalt used in NCM precursors for lithium battery cathode material use mine refining salt. For example, a major Chinese metal salt manufacturer dissolves several types of semi-finished products from the mine, then undergoes an extraction process to produce high-purity products.

◇Metal salts of nickel and cobalt, which have been separated from waste cells, are currently used in small quantities, but recycling of waste cells will play an essential role in the industry at a time when the electric vehicle market will grow and become saturated.

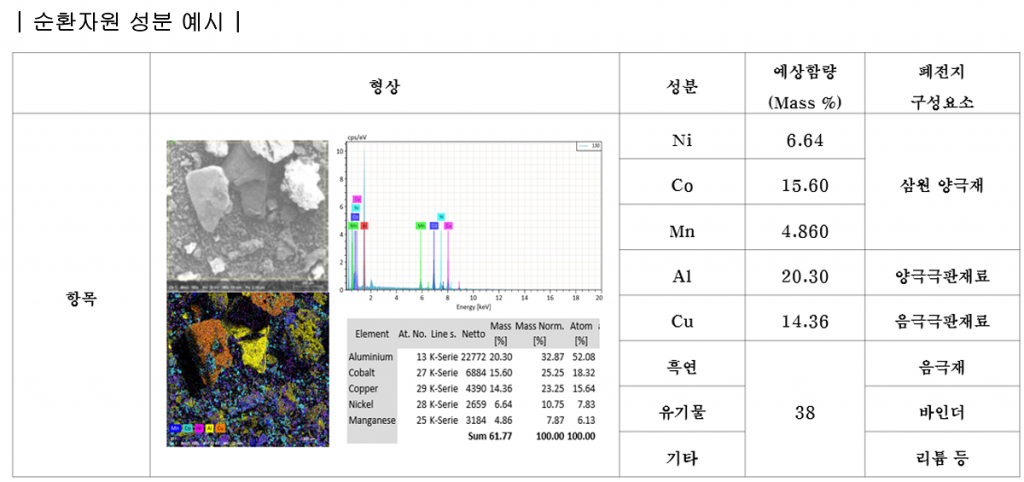

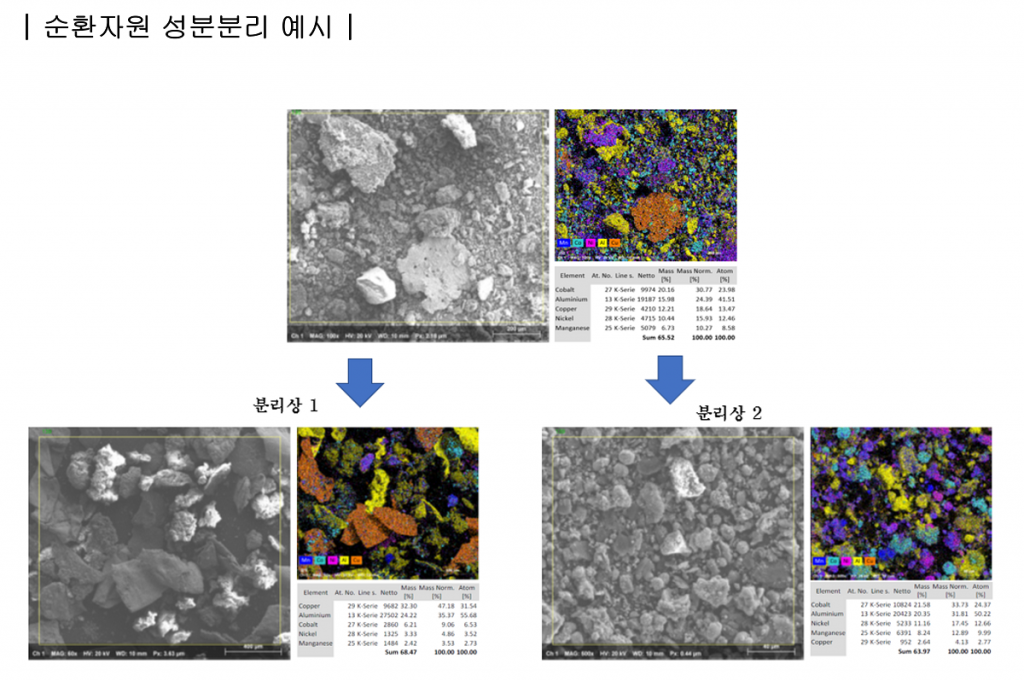

◇ From the perspective of recycling resources, the lithium secondary battery cathode material industry has a circular structure of ‘raw materials (recycling) – metallic salts (e.g. nickel sulfate, cobalt sulfate) – precursors – cathode materials – lithium secondary batteries – raw materials (recycling). In line with this direction, industrial preparations to secure and recycle waste batteries by resources are ongoing worldwide.

◇ In line with the flow of the circulating resource industry, rov Co., Ltd. is devoted to the development of waste resource distribution structure and the development of resource extraction and purification technology. If high purity metal salt manufacturing technology, Korea’s weak industry, is successfully combined with its eco-friendly precursor manufacturing technology, it is expected to cause major synergies in the future circulation business.